Stock is broken up into 2 area's.

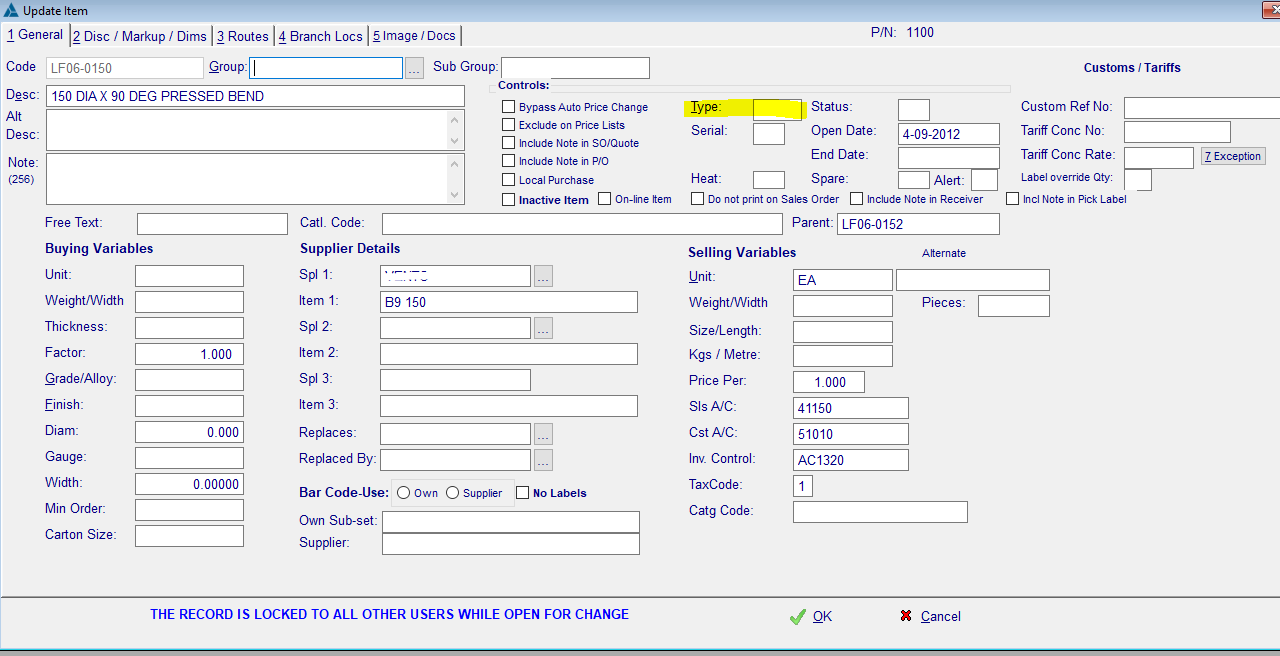

Master data

Contains the GL codes, Supplier details, Buying / selling Variables etc.

Type Field

| Code | Meaning | Description |

|---|---|---|

| '' | Blank | Normal stock item. |

| B | Buy in | Where system accumulates cost in the average field and each sale is specifically costed and not average costed. Cost is accumulated as the item is either a generic group or manufactured/imported where the cost varies - for whatever reason - and must go out at its stocking cost. It uses that cost on the sales order. |

| A | Auto update | Update sell prices (1 to 4) based on markup pcts in M/U profile in Discount Tab when receiving from Del Dkts or Spl Invoice. Used mostly when the 'base' cost is a factor of the Copper / Nickel or other index and needs to be changed regularly. |

| K | Kit | Sold from assembled elements at sales order time |

| P | Price lookup | Price lookup item only, doesn't increment stock on invoicing |

| L | Length | Stock in lengths, not metres |

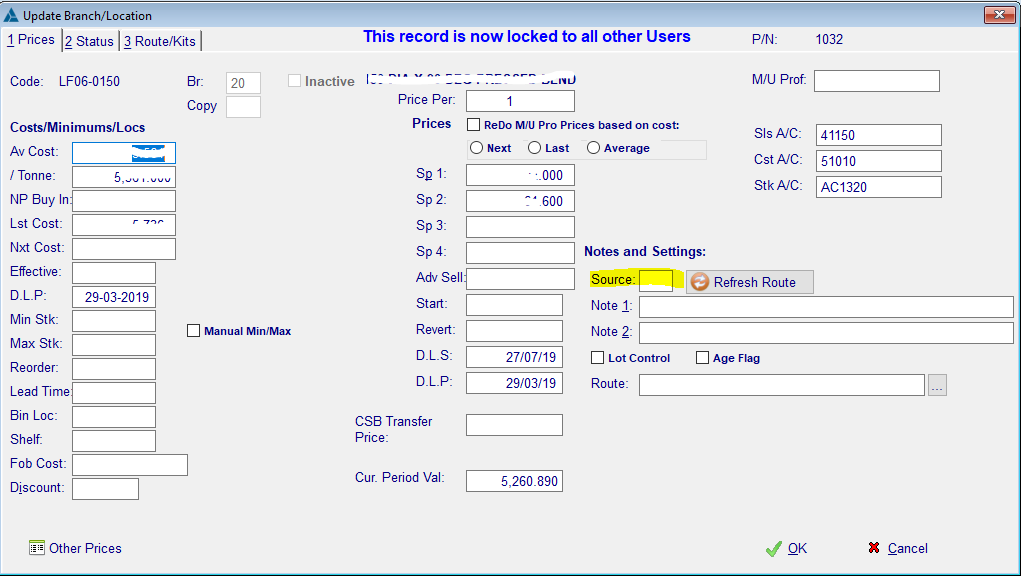

Branch Locations

Contains data that could change between branches.

Source field

| Code | Meaning | Description |

|---|---|---|

| W | Work Order | Made from a Work Order for a sales order. The cost on the sales order is updated when the work order is stocked. |

| M | Manufacturing | Manufacturing work order for inventory replenishment. The Works order for these items need to be manually generated. The Sales Order will use the Average cost from the Branch location. |

| P | Purchased | Purchased buy in item for linking with a sales order. The cost is linked to the Purchase Order. |

| O | Order | Order in directly onto a works order - not through stock receipts, hence doesn't update the values in the Stock Ledger. |

| ?? | Branch | Branch where source from if not carried in stock. |

('P' 'O' & ?? will not have system generated min/max levels)